September 19, 2016

by Andrey Filippov

Since we started to deliver first NC393 series cameras in May we were working on the cameras software – original version was rather limited. While it was capable of serving images/video over the network and recording them on the internal m.2 SSD, it did not have the advanced image acquisition control (through the GUI and programmatically) that was standard for the earlier NC353 series. Now the core functionality is operational and in a month we plan to have the remaining parts (inter-camera synchronization, working with multiple sensors per-port with 10359 multiplexer, GPS+IMU logging) online too. FPGA code is already ported, but it needs to be tested and a fair amount of troubleshooting, identifying the problems and weeding out the bugs is still left to be done.

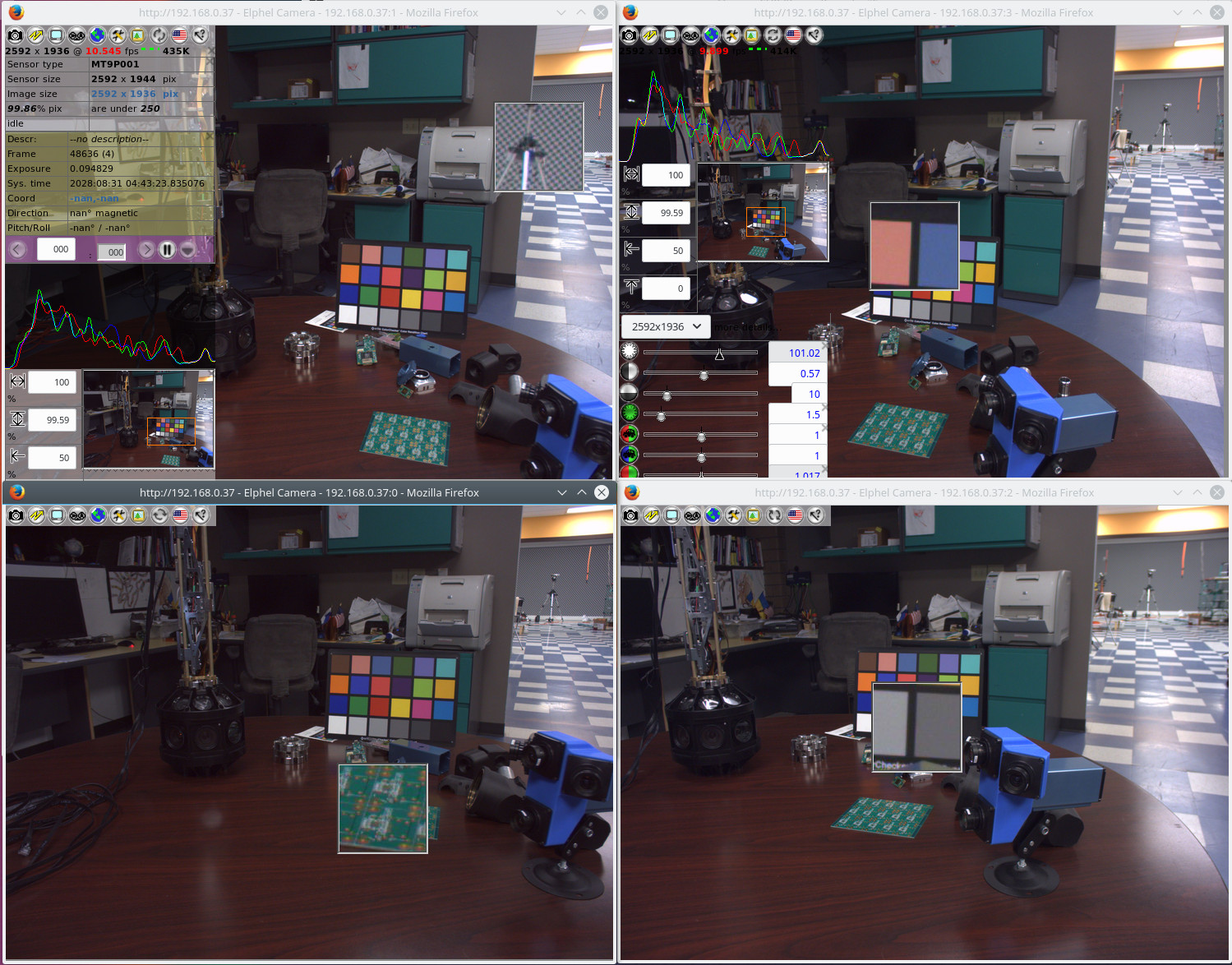

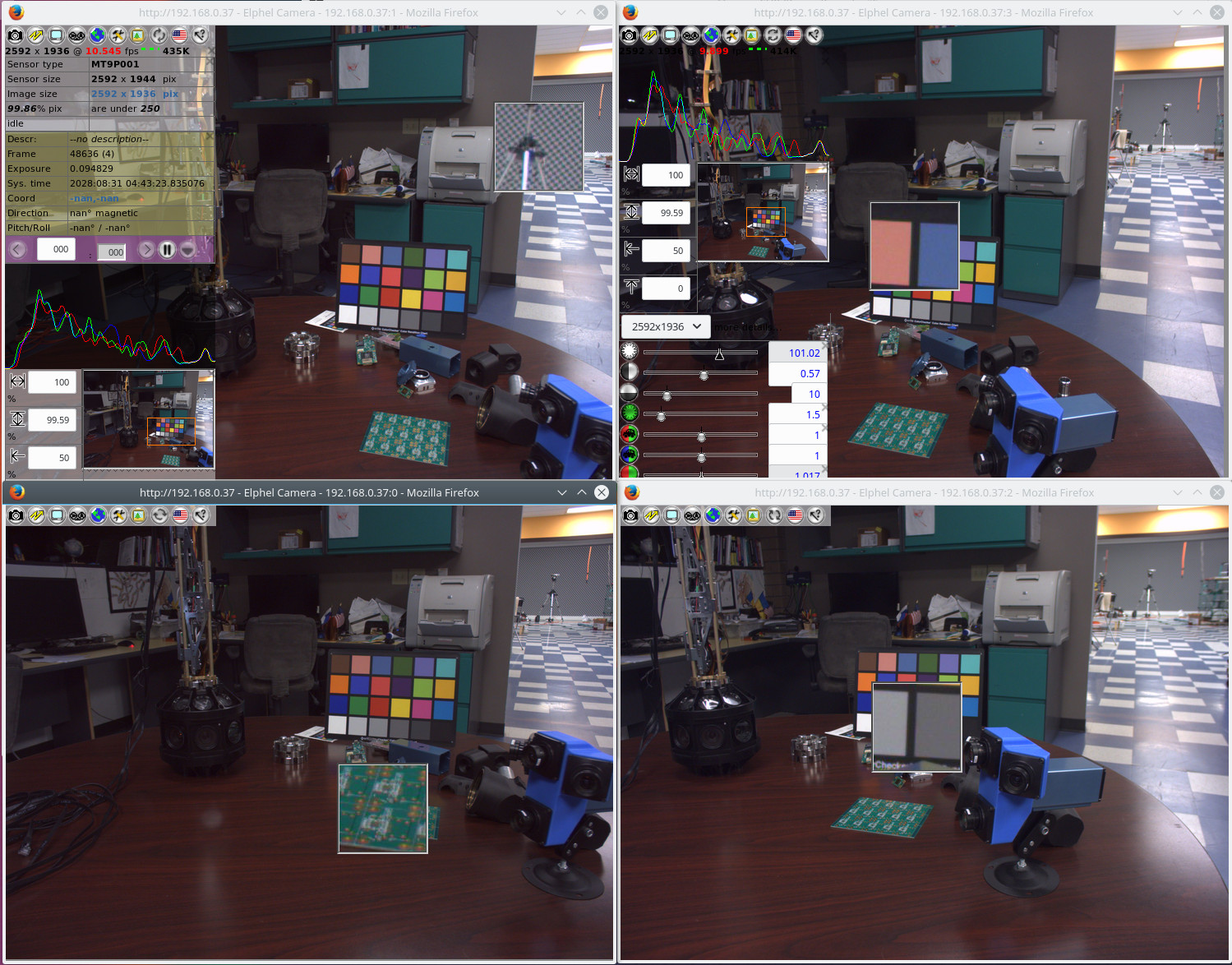

Fig 1. Four camvc instances for the four channels of NC393 camera

Users of earlier Elphel cameras can easily recognize familiar camvc web interface – Fig. 1 shows a screenshot of the four instances of this interface controlling 4 sensors of NC393 camera in “H” configuration.

(more…)

September 13, 2016

by Mikhail Karpenko

Introduction

Elphel cameras use camogm, a user space application, for recording acquired images to a disk storage. The application is developed to use such storage devices as disk drives or USB drives mounted in the operating system. The Elphel393 model cameras have SATA-2 controller implemented in FPGA, a system driver for this controller, and they can be equipped with an SSD drive. We were interested in performing write speed tests using the SATA controller and a couple of M.2 SSDs to find out the top disk bandwidth camogm can use during image recording. Our initial approach was to try a commonly accepted method of using hdparm and dd system utilities. The first disk was SanDisk SD8SMAT128G1122. According to the manufacturer specification [pdf], this is a low power disk for embedded applications and this disk can show 182 MB/s sequential write speed in SATA-3 mode. We had the following:

|

|

~# hdparm -t /dev/sda2 /dev/sda2: Timing buffered disk reads: 274 MB in 3.02 seconds = 90.70 MB/sec ~# time sh -c "dd if=/dev/zero of=/dev/sda2 bs=500M count=1 && sync" 1+0 records in 1+0 records out real 0m6.096s user 0m0.000s sys 0m5.860s |

which results in total write speed around 82 MB/s.

(more…)

September 8, 2016

by Oleg Dzhimiev

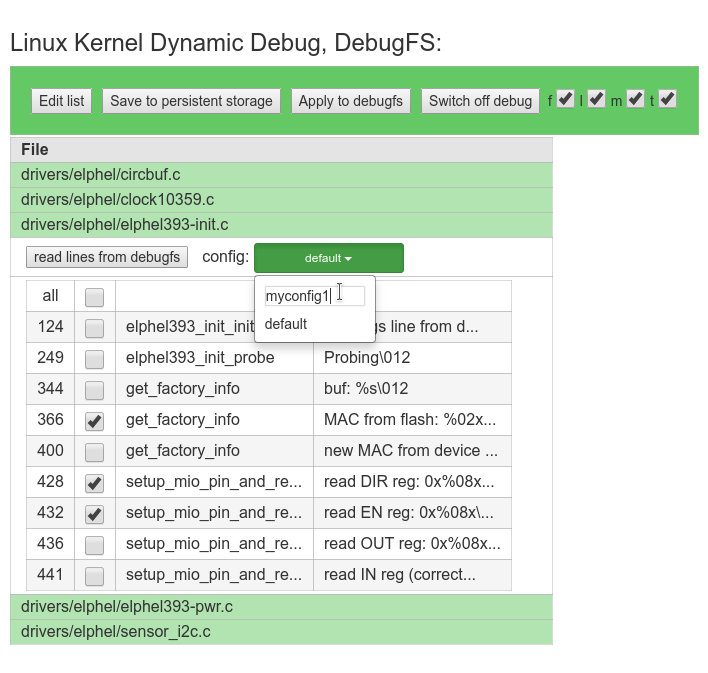

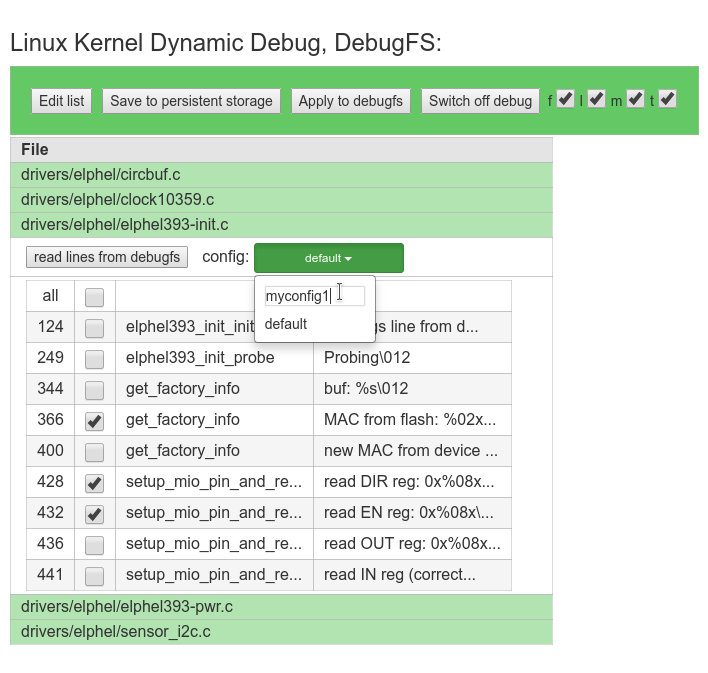

Along with the documentation there is a number of articles explaining the dynamic debug (dyndbg) feature of the Linux kernel like this one or this. Though we haven’t found anything that would extend the basic functionality – so, we created a web interface using JavaScript and PHP on top of the dyndbg.

Fig.1 debugfs-webgui

(more…)

July 11, 2016

by Andrey Filippov

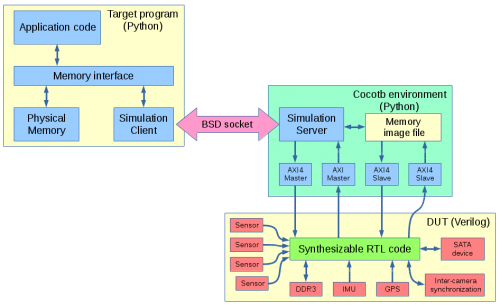

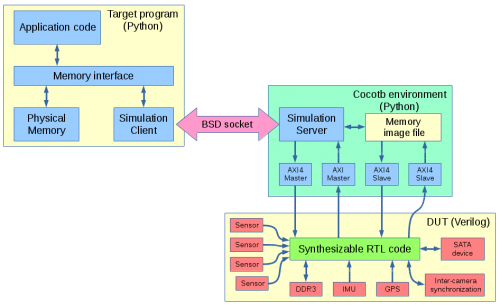

Or at least larger (verification) part of it – interfaces, packages and a few other synthesizable features are very useful to reduce size of Verilog code and make it easier to maintain. We now are able to run production target system Python code with Cocotb simulation over BSD sockets.

Client-server simulation of NC393 with Cocotb

Previous workflow

Before switching to Cocotb our FPGA-related workflow involved:

- Creating RTL design code

- Writing Verilog tests

- Running simulations

- Synthesizing and creating bitfile

- Re-writing test code to run on the target system in Python

- Developing kernel drivers to support the FPGA functionality

- Developing applications that access FPGA functionality through the kernel drivers

Of course the steps are not that linear, there are hundreds of loops between steps 1 and 3 (editing RTL source after finding errors at step 3), almost as many from 5 to 1 (when the problems reveal themselves during hardware testing) but few are noticed only at step 6 or 7. Steps 2, 5, 6+7 involve a gross violation of DRY principle, especially the first two. The last steps sufficiently differ from step 5 as their purpose is different – while Python tests are made to reveal the potential problems including infrequent conditions, drivers only use a subset of functionality and try to “hide” problems – perform recovering actions to maintain operation of the device after abnormal condition occurs.

(more…)

May 22, 2016

by Andrey Filippov

Elphel cameras offer unique capabilities – they are high performance systems out of the box and have all the firmware and FPGA code distributed under GNU General Public Licenses making it possible for users to modify any part of the code. The project does not use any “black boxes” or encrypted modules, so it is simulated with the free software tools and user has access to every net in the design. We are trying to do our best to make this ‘hackability’ not just a theoretical possibility, but a practical one.

Current camera FPGA project contains over 400 files under version control and almost 100K lines of HDL (Verilog) code, there are also constraints files, tool configurations, so we need to provide means for convenient navigation and modification of the project by the users.

We are starting a series of tutorials to facilitate acquaintance with this project, and here is the first one that shows how to install and configure the software. This tutorial is made with a fresh Kubuntu 16.04 LTS distribution installed on a virtual machine – this flavor of GNU/Linux we use ourselves and so it is easier for us to help others in the case of problems, but it should be also easy to install it on other GNU/Linux systems.

Later we plan to show how to navigate code and view/modify tool parameters with VDT plugin, run simulation and implementation tools. Next will be a “Hello world” module added to the camera code base, then some simple module that accesses the video memory.

Video resolution is 1600×900 pixels, so full screen view is recommended.

Download links for: video and captions.

Running this software does not require to have an actual camera, so it may help our potential users to evaluate software capabilities and see if it matches their requirements before purchasing an actual hardware. We will also be able to provide remote access to the cameras in our office for experimenting with them.

May 10, 2016

by Andrey Filippov

Two weeks ago we were making photos of our first production NC393 camera to post an announcement of the new product availability. We got all the mechanical parts and most of the electronic boards (14MPix version will be available shortly) and put them together. Nice looking camera, powered by a high performance SoC (dual ARM plus FPGA), packaged in a lightweight aluminum extrusion body, providing different options for various environments – indoors, outdoors, on board of the UAV or even in the open space with no air (cooling is important when you run most of the FPGA resources at full speed). Tons of potential possibilities, but the finished camera did not seem too exciting – there are so many similar looking devices available.

NC393 camera, back panel view. Includes DC power input (12-36V and 20-75V options), GigE, microSD card (bootable), microUSB(type B) connector for a system console with reset and boot source selection, USB/eSATA combo connector, microUSB(type A) and 2.5mm 4-contact barrel connector for external synchronization I/O

NC393 assembled boards: 10393(system board), 10385 (power supply board), 10389(interface board), 10338e (sensor board) and 103891 - synchronization adapter board, view from 10389. m.2 2242 SSD shown, bracket for the 2260 format provided. 10389 internal connectors include inter-camera synchronization and two of 3.3VDC+5.0VDC+I2C+USB ones.

NC393 assembled boards: 10393(system board), 10385 (power supply board), 10389(interface board), 10338e (sensor board) and 103891 - synchronization adapter board, view from 10385

10393 system board attached to the heat frame, view from the heat frame. There is a large aluminum heat spreader attached to the other side of the frame with thermal conductive epoxy that provides heat transfer from the CPU without the use of any spring load. Other heat dissipating components use heat pads.

10393 system board attached to the heat frame, view from the 10393 board

10393 system board, view from the processor side

An obvious reason for our dissatisfaction is that the single-sensor camera uses just one of four available sensor ports. Of course it is possible to use more of the freed FPGA resources for a single image processing, but it is not what you can use out of the box. Many of our users buy camera components and arrange them in their custom setup themselves – that does not have a single-sensor limitation and it matches our goals – make it easy to develop a custom system, or sculpture the camera to meet your ideas as stated on our web site. We would like to open the cameras to those who do not have capabilities of advanced mechanical design and manufacturing or just want to try new camera ideas immediately after receiving the product.

(more…)

April 21, 2016

by Olga Filippova

We have created a short video tutorial to help our users navigate through 3D models of Elphel cameras. Cameras can be virtually taken apart and put back together which helps to understand the camera configuration and access information about every camera component. Please feel free to comment on the video quality and usefulness, as we are launching a series of tutorials about cameras, software modifications, FPGA development on 10393 camera board, etc. and we would like to receive feedback on them.

(more…)

March 30, 2016

by Andrey Filippov

Elphel NC393 as all the previous camera models relies on the intimate cooperation of the FPGA programmed in Verilog HDL and the software that runs on a general purpose CPU. Just as the FPGA manufacturers increase the speed and density of their devices, so do the Elphel cameras. FPGA code consists of the hundreds of files, tens of thousand lines of code and is constantly modified during the lifetime of the product both by us and by our users to accommodate the cameras for their applications. In most cases, if it is not just a bug fix or minor improvement of the previously implemented functionality, the software (and multiple layers of it) needs to be aware of the changes. This is both the power and the challenge of such hybrid systems, and the synchronization of the changes is an important issue.

(more…)

March 18, 2016

by Oleg Dzhimiev

Overview

- Target board: Elphel 10393 (Xilinx Zynq 7Z030) with 1GB NAND flash

- U-Boot final image files (both support NAND flash commands):

- boot.bin – SPL image – loaded by Xilinx Zynq BootROM into OCM, no FSBL required

- u-boot-dtb.img – full image – loaded by boot.bin into RAM

- Build environment and dependencies (for details see this article) :

(more…)

by Andrey Filippov

We added the AHCI SATA controller Verilog code to the rest of the camera FPGA project, together they now use 84% of the Zynq slices. Building the FPGA bitstream file requires proprietary tools, but all the simulation can be done with just the Free Software – Icarus Verilog and GTKWave. Unfortunately it is not possible to distribute a complete set of the files needed – our code instantiates a few FPGA primitives (hard-wired modules of the FPGA) that have proprietary license.

Please help us to free the FPGA devices for developers by re-implementing the primitives as Verilog modules under GNU GPLv3+ license – in that case we’ll be able to distribute a complete self-sufficient project. The models do not need to provide accurate timing – in many cases (like in ours) just the functional simulation is quite sufficient (combined with the vendor static timing analysis). Many modules are documented in Xilinx user guides, and you may run both the original and replacement models through the simulation tests in parallel, making sure the outputs produce the same signals. It is possible that such designs can be used as student projects when studying Verilog.

(more…)

« Previous Page —

Next Page »