June 20, 2014

by Andrey Filippov

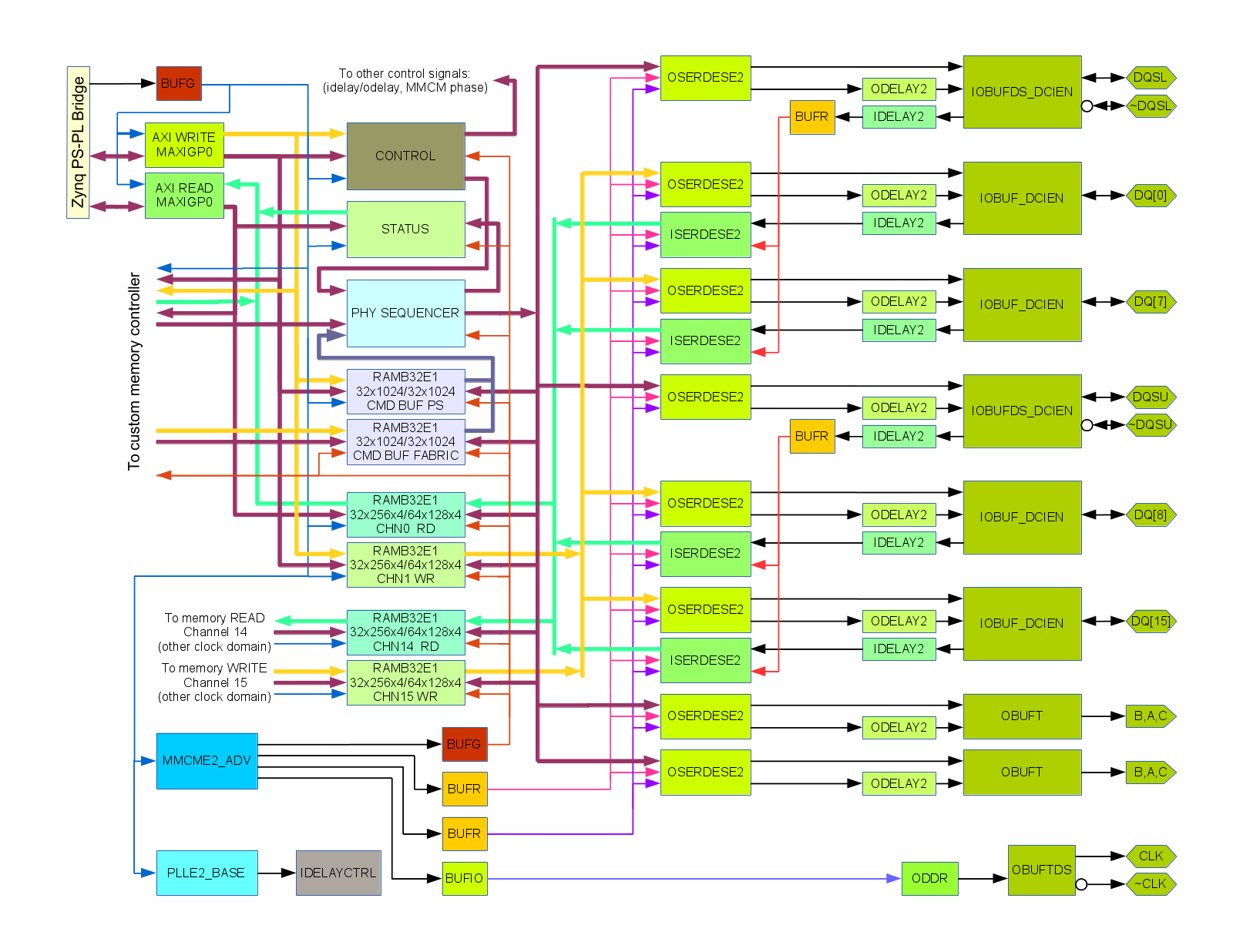

External memory controller is an important part of many FPGA-centered designs, it is true for Elphel cameras too. When I was working on the board design for NC393 I tried to verify inteface pinout using the code output from the MIG (Memory Interface Generator) module. I was planning to use MIG code as a reference design and customize it for application in the camera, adding more functionality to our previous designs. Memory interface is a rather intimate part of the design where FPGA approach can shine it all its glory – advance knowledge of the types of needed memory transactions (in contrast with the general CPU system memory) helps to increase performance by planning bank and address sequences, crafting memory mapping to utilize close to 100% of the bus bandwidth.

(more…)

March 31, 2014

by Alexandre

University of Geneva

Monday, April 14, 2014 – 18:15 at Uni-Mail, room MR070, University of Geneva.

Elphel, Inc. is giving a conference entitled “High Performance Open Hardware for Scientific Applications”. Following the conference, you will be invited to attend a round-table discussion to debate the subject with people from Elphel and Javier Serrano from CERN.

Javier studied Physics and Electronics Engineering. He is the head of the Hardware and Timing section in CERN’s Beams Control group, and the founder of the Open Hardware Repository. Javier has co-authored the CERN Open Hardware Licence. He and his colleagues have also recently started contributing improvements to KiCad, a free software tool for the design of Printed Circuit Boards

Elphel Inc. is invited by their partner specialized in stereophotogrammetry applications – the Swiss company Foxel SA, from April 14-21 in Geneva, Switzerland.

You can enjoy a virtual tour of the Geneva University by clicking on the links herein below:

(make sure to use the latest version of Firefox or Chromium to view the demos)

Foxel’s team would be delighted to have all of Elphel’s clients and followers to participate in the conference.

A chat can also be organized in the next few days. Please contact us at Foxel SA.

If you do not have the opportunity to visit us in Geneva, the conference will be streamed live and the recording will be available.

December 17, 2013

by Andrey Filippov

The software used in the previous Elphel cameras was based on the GNU/Linux distribution supported By Axis Communications for their ETRAX processors. Of course it was heavily modified, we developed new code and ported many applications to run in the camera. Over the years we worked on making it easier to install, use and update, provided customized Live GNU/Linux distributions so those with zero experience with this operating system can still use the camera development software. Originally we used Knoppix-based CD, then DVD, then switched to Kubuntu when it became available and stable. And DVDs were eventually replaced by the USB flash drives.

(more…)

November 7, 2013

by Andrey Filippov

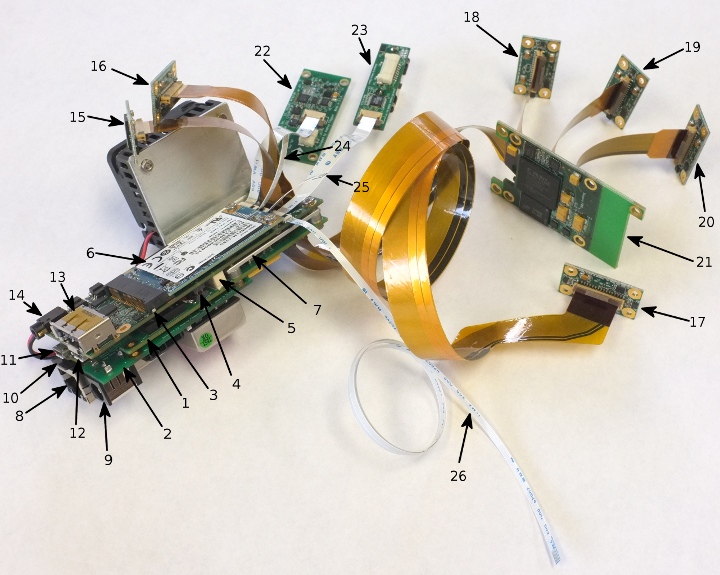

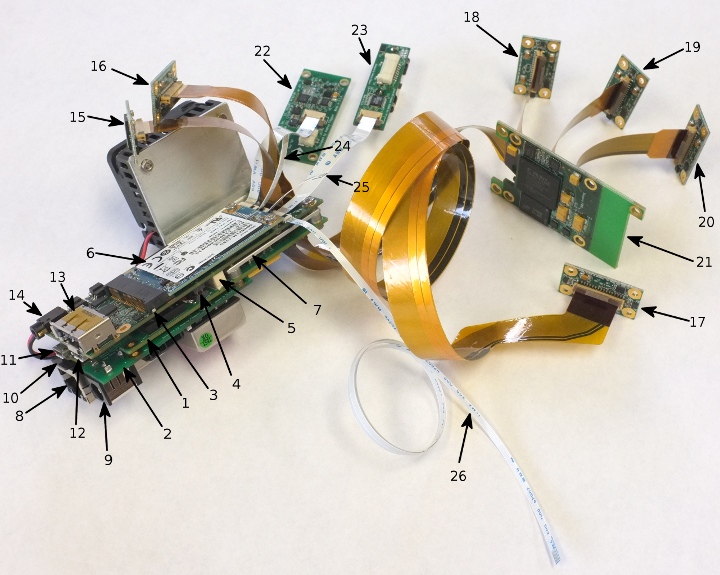

With all three of the new boards for the NC393 series cameras assembled (but only partially tested) it is now possible to connect them with the existent components and show some possible configurations. Main applications of Elphel cameras are scientific research, system prototyping, proofs of concepts designs – areas that routinely require unique configurations, and this new camera series will continue tradition of high modularity.

The camera boards look nothing like Lego blocks, but nevertheless they can zip together in different ways allowing to make new systems with minimal additional hardware. Elphel new design values our prior work (hardware development is still expensive) and provides compatibility with the existent modules, simultaneously enabling new features that were not previously possible, The most obvious example – sensor interface. The 10393 board is designed to accommodate our existent sensor front ends, custom flex cables of different lengths and shapes. That will help us to reduce the transition period to the new camera so we can focus on the high performance system board and port portions of the software and FPGA code, code that is already proven to work.

The same camera sensor ports will allow us to use multi-lane serial sensor connections needed for the modern high speed and high resolution devices, but we will work on this only after the first part will be done and we will be able to replace our current systems with the new ones. Implementation of the serial sensor connection has some challenges for us because the used protocols are not open and we have to rely only on the pieces of the available information and some reverse-engineering and research. It is not the most fun work to do, but being an Open Hardware/ Free Software company we will not provide our users with semi-open documentation. Our users will always be able to rebuild all the binaries from the source code – same binaries from the same code we have access ourselves. The only NDA Elphel ever signed was with Kodak – that sensor NDA had clear expiration time, so at the moment we planned to start distributing our products (and so the source documentation) we were not be bound by it anymore.

Sample configuration illustrated below combines the new and existent modules, the later have links to the design documentation on Elphel wiki. It is not so for the new boards (10393, 10385, 10389) – no circuit diagrams, parts lists or PCB layouts are publicly available when this post is being written. Hardware errors are usually much more expensive to fix, and we do not want somebody to duplicate our hardware “bugs” until we consider our products (“binaries”) to be good enough to go to our users. So while we set up public Git repository when we start software development, we publish our hardware documentation simultaneously with the start of the product distribution – together with “binaries”, not ahead of them.

Sample configuration of the electronic modules of Elphel NC393 camera family

November 2, 2013

by Andrey Filippov

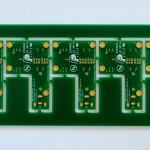

10393 board, memory side

We received the first prototype of the 10393 rev.’0″ – the new camera system board with all the BGA chips mounted. It took a little longer as our PCB assembly manufacturer had to order solder paste stencils as some chips (DC-DC converter module in LGA package and QFN chips with central thermal pads) required more than just applying tacky flux and running them through the reflow oven. The photo shows the 10393 system board together with the 10385 power supply board that I assembled earlier while waiting for the main one. This time the power supply is a separate module so we’ll not need different system board versions for different power supply options as we do with Elphel current NC353.

(more…)

October 29, 2013

by flight-machine

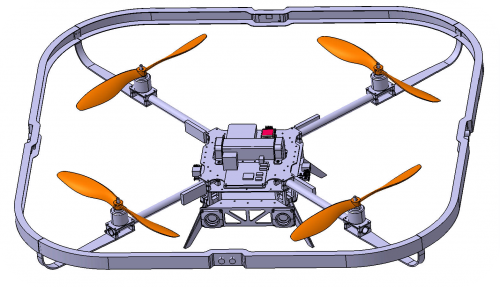

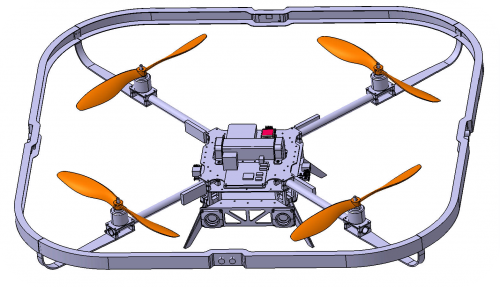

This page gives brief overview of multirotor UAV platform called “Tau”, which is built specially for participating in flying robots contest which is established by Russian Croc company. For now contest has only russian participants, probably because it was made for a first time.

Our team name was “Autonomous aerospace”. We are from Krasnoyarsk, 1M people city in Siberia. We had experience in UAV airplane development and manufacturing. We’ve grew up from student and postgraduate student university (SFU) scientific team to startup company.

(more…)

October 2, 2013

by Andrey Filippov

In this post I write about our current development, my first experience with Xilinx Zynq, and also try to summarize the 10+ years experience with Xilinx FPGA devices. It is a mixture of the admiration for their state of the art silicon devices and frustration caused by the software. Please excuse my sometimes harsh words and analogies – I really would like to see Xilinx prosper and acquire software vision that matches the freedom that Ross Freeman brought to developers of the electronic devices when he invented FPGA and started Xilinx.

(more…)

October 1, 2013

by Andrey Filippov

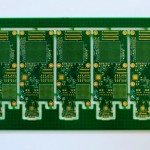

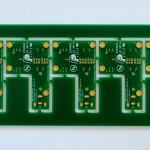

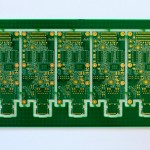

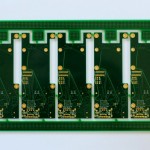

Just a small update – we received all the 3 boards ordered for the NC393 camera at Fastprint, China. We will have our contract manufacturer install the BGA chips, and then I’ll work again on the tiny 0201 components, like 4 years ago. I love to assemble such boards (but not too often) myself – going through all the components when they are real (not virtual) gives me a different perspective to think about the design.

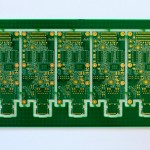

10393 System board, top side |

10389 Interface board, top side |

10385 Power supply board, top side |

10393 System board, bottom side |

10389 Interface board, bottom side |

10385 Power supply board, bottom side |

July 27, 2013

by Andrey Filippov

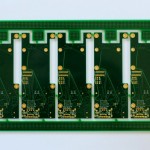

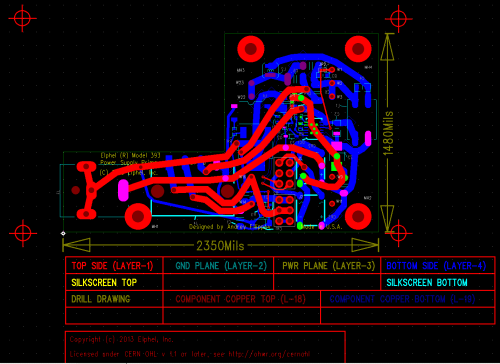

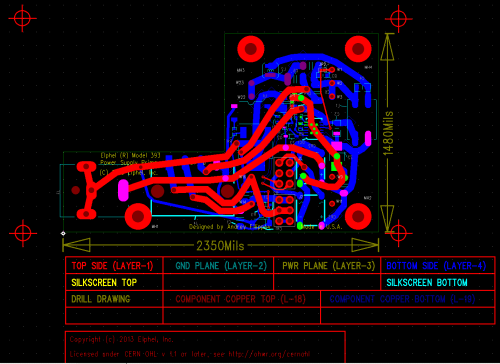

10385 – Power supply board layout

There is a small update to the previous post – circuit design and the PCB layout is done for the two companion boards. And it lead to some re-design on the system board. When working on the power supply board (it provides camera with the regulated 3.3V from the external source) I realized that it will have to hang on just two screws – not good for a rather heavy board with Traco DC/DC module (same size as the one currently used in Elphel NC353L camera). The 10393 system board and the 10389 Interface/SSD boards will be mounted on two sides of the aluminum heat sink plate (CNC-ed to match component heights) and the smaller 10385 will sit on top of the 10393, and all the 10385 mount screws have to go through the system board. So I had to add additional holes near the middle of the 10393. That in turn required to move the 40-pin inter-board connector that carries SATA, USB, synchronization and additional general purpose signals to the 10389. So I had to re-route part of the design, but it was a right time to do as none of the boards was released yet leaving the freedom for such modifications. These new holes will also improve the mounting of the heat sink to the Zynq chip (the large white square on the 10393 layout below).

(more…)

July 13, 2013

by Andrey Filippov

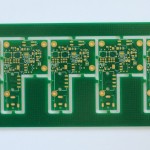

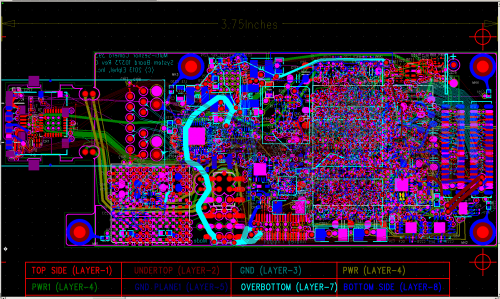

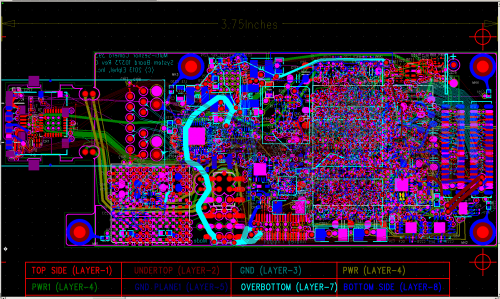

Development of the NC393 is now started, at last – last 6 weeks I’m working on it full time. It is still a long way ahead before the new camera will replace our current model 353, but at least the very first step is completed – I just finished the PCB layout of the system board.

10393 System Board PCB layout

There were not so many changes to the specs/features that were planned and described in the October 2012 post, the camera will be powered by Xilinx Zynq SoC (XC7Z030-1FBG484C to be exact) that combines high performance FPGA with a dual ARM CPU and generous set of built-in peripherals. It will have 1GB of on-board system memory and 512MB of additional dedicated video/FPGA memory (the NC353 has 64MB each of them). Both types of memory consist of the same 256Mx16 DDR3 chips – 2 for the system (to use full available memory bus width of 32 bits) and one for the FPGA.

The main class of the camera applications remains to be a multi-sensor. Even more so – the smallest package of the Zynq 7030 device turned out to have sufficient number of I/Os to accommodate 4 sensor ports – originally I planned only 3 of them. These sensor ports are fully compatible with our current 5MPix sensor boards and with the existent 10359 sensor multiplexer boards – with such multiplexers it will be possible to control up to 12 sensors with a single 10393. Four of the connectors are placed in two pairs on both sides of the PCB, so they overlap on the layout image.

(more…)

« Previous Page —

Next Page »